Fasteners Plant

Kadevi Fasteners Division is equipped with :

- Four Station of Bolt Making Machinery consisting of header machine/Trimming/Thread Machine

- Four Station of Nut forming machine and ten nut tapping machines tomanufacture M8 to M24 and DIA 5/16" to 7/8" respectively.

- Two Galvanising Plants.

- Two sets of automatic Bolts, Nuts assembly machines.

- In house workshop for Tools making.

|

|

| Wire Drawing Machine : The raw material received in the form of coils/rods are subjected for cleaning in HCL and Phospating process. Subsequently the coils are fed into drawing machine and will be drawn to exact size required to ensure roundness of the coil rod. |

Nut Forming Machine : The required size of coil will be fed into the machine which are fully automatic and finished product of nuts (blank) are formedin 5 stage operation. The present production range is from M8 to M24 with four stations of machinery installed. |

|

|

| Nut Tapping Machine : The nuts are tapped by automatic hopper nut Tapping machines with double spindle for the most accurate and utmost quality threading. We have 10 nut Tapping Stations. |

Bolt Header Machine : The required coil is fed into the fully automatic bolt head forming machine. The output is in the form of round head with required length of bolt. We are equipped with four stations of bolt making machines manufacturing different sizes from M8 to M24 & DIA ½" to 1". |

|

|

| Bolt Trimming Machine : The semi finished bolts received from the header are fed into this machine which converts the round head into hexagonal head and the length of the Bolt is trimmed to the required size. The bolts are automatically fed by a conveyor system. |

Bolt Thread Machine : The semi finished bolts received from the trimming machine are fed into this machine which forms threading 9half/full). The bolts are automatically fed by a conveyor system. |

|

|

| Galvanising Plant : The machined bolts & nuts are cleansed by a chemical process vide pickling, cleaning, fluxing and finally sent for pre-heat treatment. After chemical process bolts & nuts are dipped into the galvanising kettle at well maintained Temperature of 450 Degrees. Out hot dip galvanising plant is a state of the art plant confirming to IS Specifications. |

Assembly Machine : The galvanized bolts & nuts are fed into the assembly machine separately through conveyer system which automatically assembles the nuts to the bolts to a prescribe length to ensure that proper mating of the bolts & nuts. |

|

|

|

Packing : We pack our bolts & nuts in a standard pack of 50 kgs in double lined gunny bags with polypropylene exclusively developed. These bags are very robust in construction and every bag is filled 50 kgs of fasteners duly assembled with a electronic weighing machine. |

Quality Assurance :

Our quality management system ensure high level of quality by inspection of incoming material and mandatory quality checks at every stage throughout the manufacturing process. Our highly equipped quality and testing facility enables us to deliver superior quality products confirming to Indian/International standards and achieve total customer satisfaction.

In Process inspection :Online inspection will be carried out at every stage with suitable jigs & gauges to ensure the required specifications as defined in the standards.

Final Inspection :Final Inspection check is carried out to ensure that Product Quality is in conformance with specified requirements.

Inspection and Test Reports/Records are maintained to establish that the product has passed inspection and testing in accordance criteria defined in the Inspection and Testing Procedures. Records are maintained for calibration and verification of monitoring and measuring equipments. We are ISO 9001- 2008 certified for well maintained Quality Management Systems by NQA-UKAS.

Test Equipment :

- Emission Spectrometer for material analysis

- Universal Testing Machine for Tensile/ Compression/Shear Tests.

- Hardness Testing Machine for Checking Hardness (Brinell & Rockwell).

- Profile Projector for measuring the thread profile/contours etc..

- Other measuring Instrument, Gauges etc.. to confirm to Specification & Drawings.

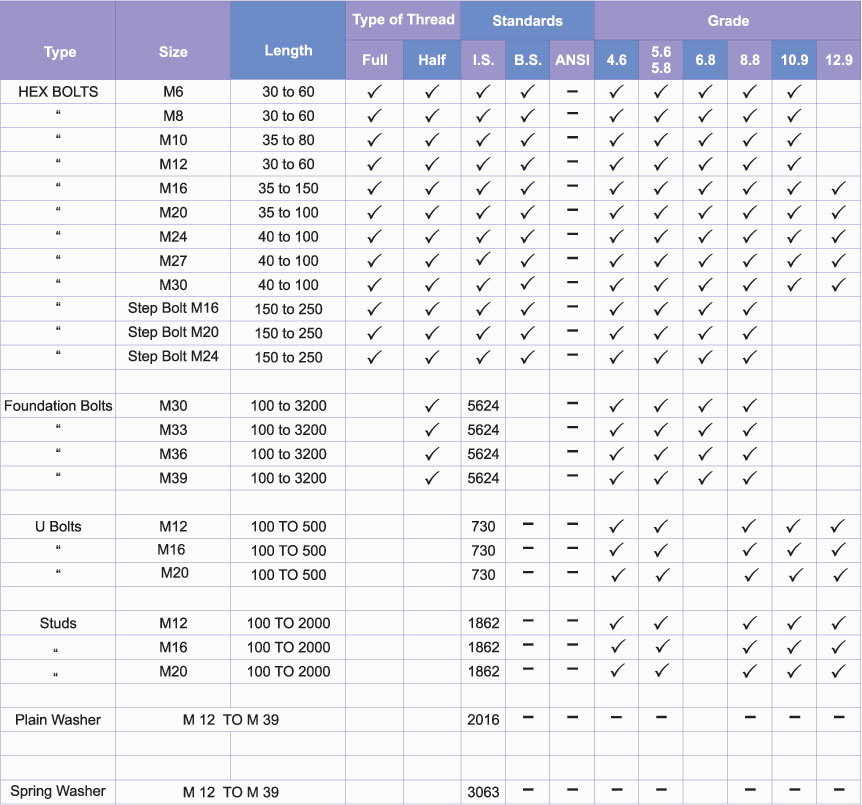

Production Range :